Abstract

Many manipulation tasks require careful force modulation. With insufficient force the task may fail, while excessive force could cause damage. The high cost, bulky size and fragility of commercial force/torque (F/T) sensors have limited large-scale, force-aware policy learning. We introduce UMI-FT, a handheld data-collection platform that mounts compact, six-axis force/torque sensors on each finger, enabling finger-level wrench measurements alongside RGB, depth, and pose. Using the multimodal data collected from this device, we train an adaptive compliance policy that predicts position targets, grasp force, and stiffness for execution on standard compliance controllers. In evaluations on three contact-rich, force-sensitive tasks (whiteboard wiping, skewering zucchini, and lightbulb insertion), UMI-FT enables policies that reliably regulate external contact forces and internal grasp forces, outperforming baselines that lack compliance or force sensing. UMI-FT offers a scalable path to learning compliant manipulation from in-the-wild demonstrations.

Video

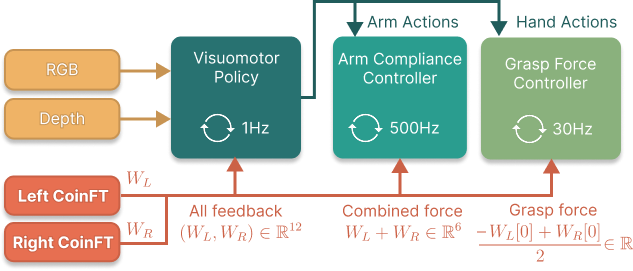

UMI-FT System Design